The DSA Revolution Advantage

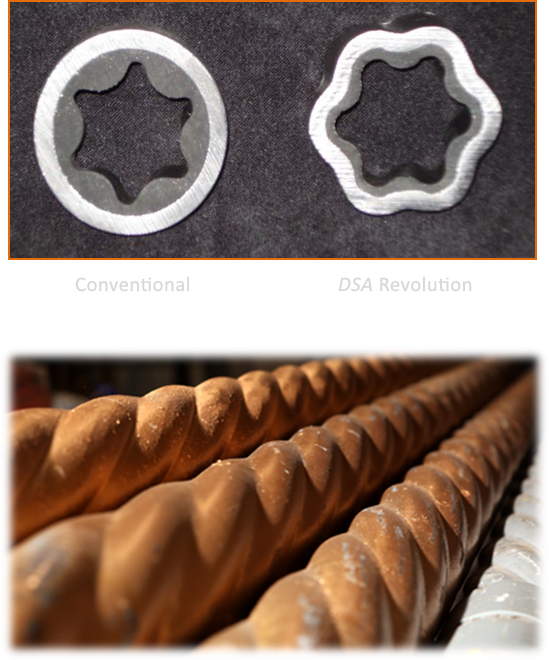

The DSA Revolution Motor incorporates E-wall, the latest innovation in mud motor stator technology. Stator performance with this even rubber thickness is greatly improved over conventional stators in all aspects. This unrivaled design nearly doubles power while also increasing longevity and resistance to temperature and harsh fluids.

The POWER is increased because the thinner rubber cross sections are supported by steel lobes formed into the housing. This provides a firmer seal which allows for higher differential pressures per unit length. Revolution stators operate at 250 psi per stage whereas conventional stators typically operate at 150 psi per stage. This increase in differential pressure is directly proportional to the increase in power.

LONGEVITY is enhanced by the reduction of rubber thickness, virtually eliminating the hysteretic effect.

Revolution stators have a greater TEMPERATURE RESISTANCE due to the uniform thickness of rubber. This translates to a very minimal amount of heat expansion (swell), making these motors much more reliable at elevated temperatures.

The uniform rubber thickness also reduces the negative effects of HARSH FLUIDS such as NITROGEN. Nitrogen impregnates stator rubber (with tiny bubbles) causing the rubber to swell. This in turn causes motors to lock up or stators to chunk. DSA Revolution motors on the other hand, have very little rubber to swell thus are far less effected. These motors are perfect for wells with low bottom hole pressures where maintaining returns may be an issue. The motor can be operated on standard fluids to begin then switched to nitrified fluids if returns are lost.